Comprehensive Development Services

accelerating your biologics journey

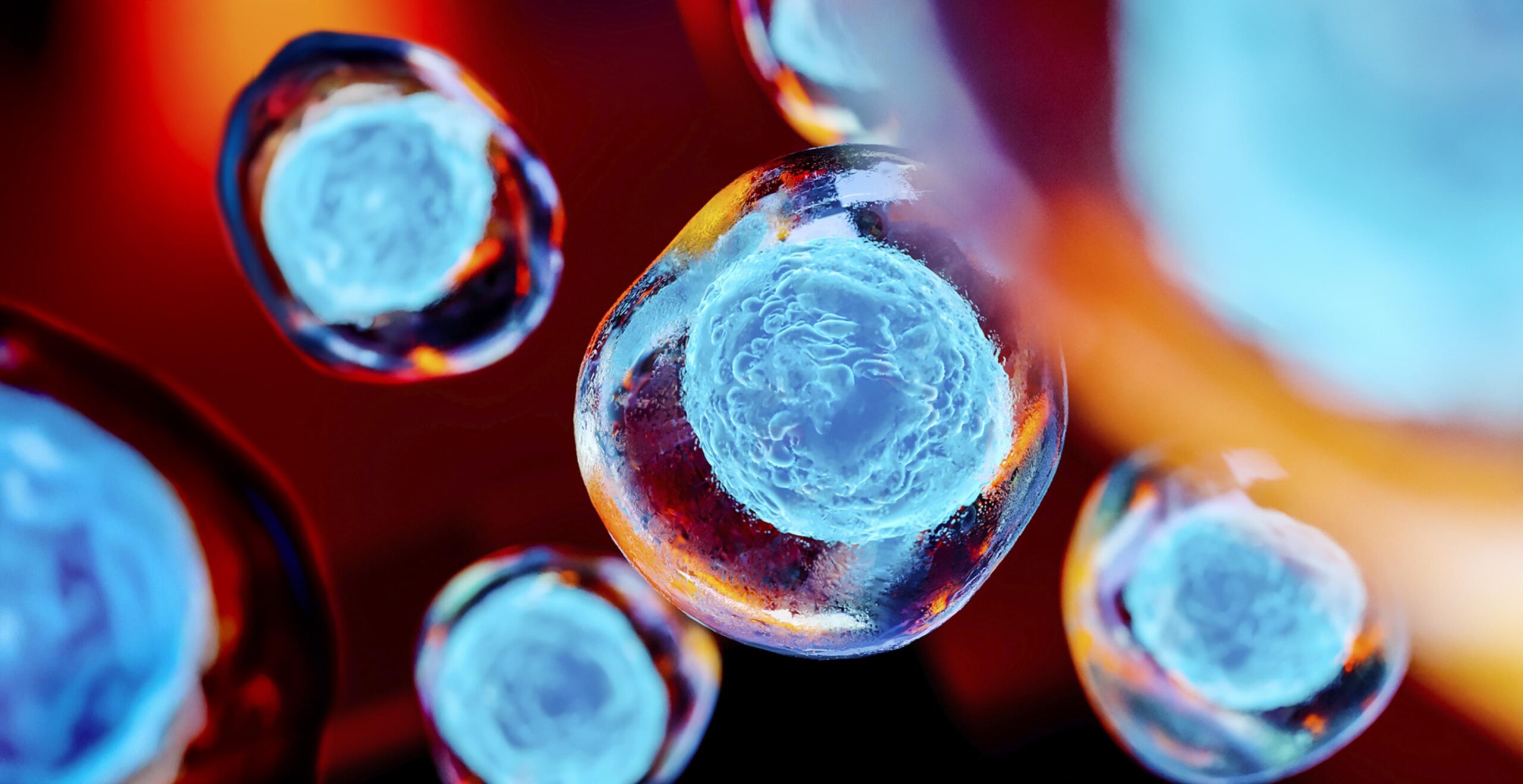

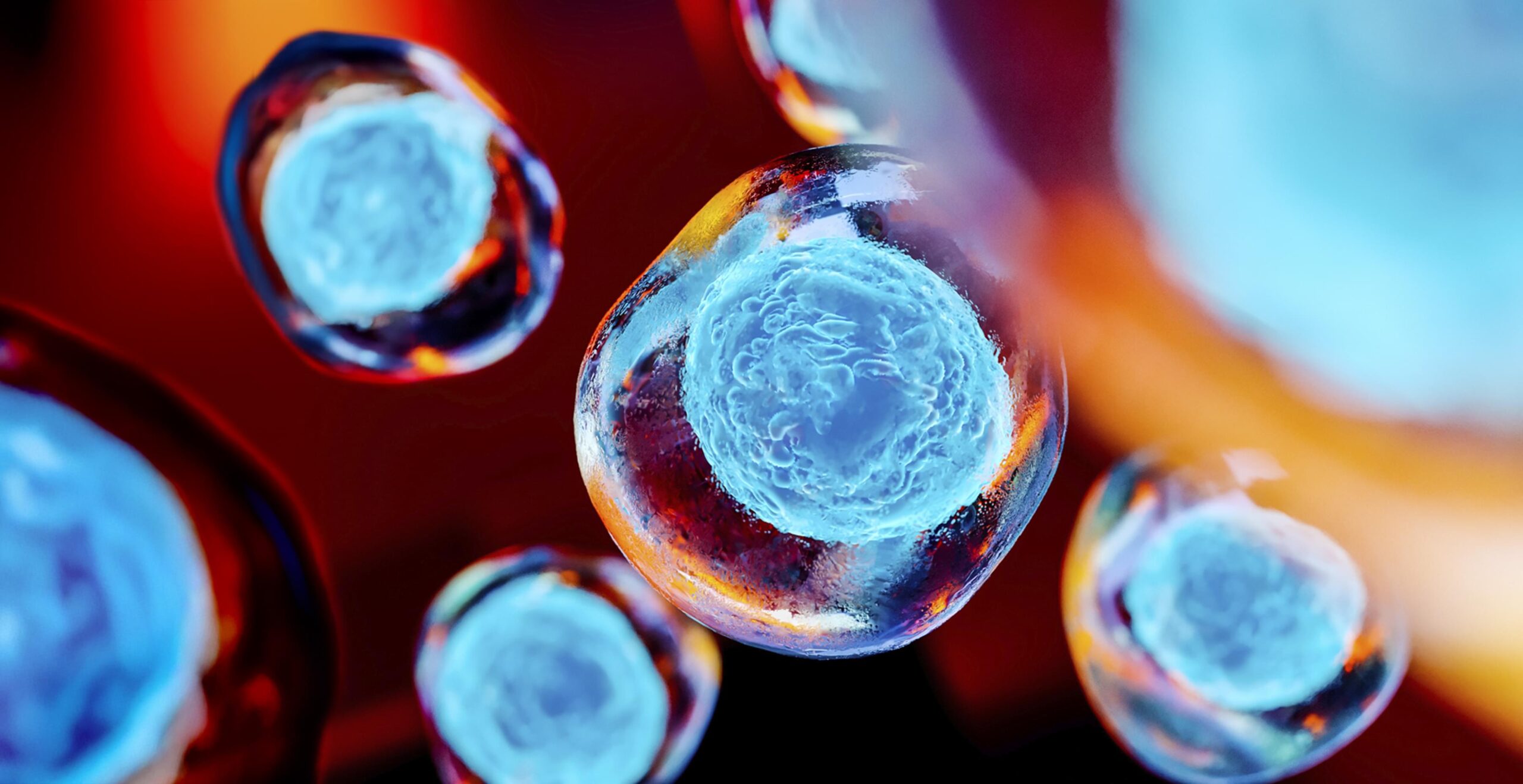

At Bora Biologics, we understand that the path from concept to commercialization is complex. Our development services are designed to streamline every stage of your biologics project, ensuring high-quality outcomes and timely delivery. With our expert team and state-of-the-art facilities, we are your trusted partner in biologics development.

Our Capabilities

We offer a wide range of development services tailored to meet your specific needs:

-

Contract

Development - Tech Transfer

-

Cell Line

Development -

Mammalian Process

Development -

Microbial Process

Development -

Analytical

Development -

Formulation & Drug

Product Development

Contract Development

Our flexible contract development services adapt to your project requirements, providing you with tailored solutions that fit your timeline and budget. We collaborate closely with you to ensure that your goals are met with precision and efficiency.

Tech Transfer

We facilitate seamless tech transfer processes, ensuring that your project transitions smoothly from development to manufacturing. Our experienced team implements best practices to maintain product integrity and compliance throughout the transfer. explore

Cell Line Development

Our robust cell line development services utilize advanced techniques to create high-yield, stable cell lines tailored to your biologics. From CHO to HEK293 systems, we ensure optimal expression levels to support your product needs. explore

Mammalian Process Development

With a focus on quality and efficiency, our mammalian process development services optimize manufacturing processes to enhance product quality and reduce costs. We employ advanced technologies to streamline workflows and ensure consistent results. explore

Microbial Process Development

Our expertise in microbial process development ensures rapid and cost-effective production of microbial-derived biologics. We utilize optimized strain selection and fermentation strategies to maximize yield and quality. explore

Analytical Development

We provide comprehensive analytical development services, including method development and validation, to ensure your product meets regulatory standards. Our analytical team is dedicated to delivering accurate and timely results to support your project.explore

Formulation & Drug Product Development

Our formulation specialists work closely with you to develop effective drug products that meet your specific requirements. We focus on stability, compatibility, and delivery methods to ensure your product’s success in the market.explore

Commitment to Quality

Quality is at the forefront of our development process. Our Quality Management System (QMS) adheres to stringent regulatory requirements, ensuring that every development stage meets the highest standards for safety, efficacy, and compliance. We conduct thorough testing and validation at each phase to guarantee product integrity.

Quality Control & Assurance

Our mature QMS employs rigorous testing protocols, ensuring the safety, identity, strength, and purity of every product.

Explore our Quality Control & Assurance processesSupply Chain Management

A robust supply chain is the backbone of a successful biopharmaceutical program, from GMP warehousing to inventory and vendor management.

Explore our Supply Chain AdvantagesProgram Management

Our timeline-driven collaborative approach ensures your vision is realized, expectations are met, and projects progress seamlessly.

Explore our Program Management philosophyProven Expertise in Biologics Development

With a track record of successful development projects, Bora Biologics has established itself as a reliable partner in the biopharmaceutical industry. Our collaborations with leading companies highlight our commitment to and excellence in biologics development.

State-of-the-Art Facilities

Our combined manufacturing footprint spans over 130,000sf featuring modular cleanrooms and advanced bioreactor systems to support large-scale production. Explore Facilities

Proven Track Record

With over 45 biologics and biosimilars developed, over 100 successful cGMP batches delivered, 2 commercially approved biosimilars in U.S. and Canada, and partnerships with leading pharmaceutical and biotech companies, we have established ourselves as a trusted partner in the biologics industry.

Expert Team

Our diverse team of scientists, engineers, and regulatory experts possesses a wealth of knowledge and experience, ensuring you benefit from the best practices in biologics manufacturing.

Let's Collaborate

If you’re ready to advance your biologics development project, contact us today. At Bora Biologics, we are dedicated to supporting your journey from concept to commercialization, ensuring that your development needs are met with expertise and precision.

Connect With UsTech Transfer

seamless transition for optimal results

At Bora Biologics, we understand that successful biopharmaceutical development relies on effective technology transfer. Our Tech Transfer process is designed to ensure a smooth and efficient transition from development to manufacturing, minimizing risks and maximizing product quality.

Our Approach to Tech Transfer

We employ a structured and collaborative approach to technology transfer that encompasses:

Comprehensive Assessment

Our team conducts an in-depth evaluation of your existing processes and technologies to identify key requirements and potential challenges. This assessment allows us to develop a tailored tech transfer plan that meets your specific needs.

Cross-Functional Collaboration

We facilitate close collaboration between development, manufacturing, and quality teams to ensure alignment and clear communication throughout the transfer process. This teamwork is essential for addressing any technical hurdles and ensuring successful implementation.

Robust Documentation

Our thorough documentation practices capture all critical information related to your processes, including protocols, specifications, and quality standards. This documentation serves as a reference throughout the tech transfer, ensuring compliance and consistency.

Commitment to Quality

During a recent tech transfer project at Bora Biologics, our MSAT team worked closely with a client to ensure a seamless transition from development to manufacturing. By identifying potential bottlenecks early, we reduced the tech transfer timeline by 25%. This collaboration not only mitigated risks but also empowered our client to advance their projects with confidence and speed.

Miguel Carrion, Vice President, Process Development & MS&T at Bora Biologics

With these competitive advantages, Bora Biologics not only ensures compliance but also enhances the reliability and success of your tech transfer, providing you with peace of mind as you move forward in your biopharmaceutical journey.

Proven Tech Transfer Track Record

With a robust history of successful tech transfers across a diverse range of biologics, Bora Biologics has firmly established itself as a trusted partner in the biopharmaceutical industry. Our commitment to excellence is reflected in several key areas:

-

Diverse

Experience -

Impressive

Production Metrics - Timely Delivery

- Client Success

-

Continuous

Improvement -

Regulatory

Expertise

Diverse Experience

Our extensive portfolio includes successful tech transfers for monoclonal antibodies, recombinant proteins, and complex biologics. This breadth of experience equips us with the insights needed to navigate various challenges unique to each product type.

Impressive Production Metrics

We have produced over 70 batches using our cGMP facility in Taiwan, achieving a remarkable 100% success rate continuously since 2014. This track record underscores our reliability and capability in executing successful tech transfers that culminate in high-quality product manufacturing.

Timely Delivery

We pride ourselves on our ability to deliver high-quality products on time, every time. Our streamlined processes and proactive project management ensure that your timelines are met, allowing you to advance your product through the development pipeline without delay.

Client Success

Numerous biopharmaceutical companies have partnered with us for their tech transfer needs, achieving successful commercialization of their products. Our successful projects highlight our ability to drive results and foster long-term relationships.

Continuous Improvement

We employ a culture of continuous improvement, regularly reviewing and refining our tech transfer processes to enhance efficiency and effectiveness. This commitment ensures that we stay ahead of industry trends and best practices.

Regulatory Expertise

Our team comprises seasoned professionals with deep knowledge of regulatory requirements across global markets. This expertise enables us to effectively navigate the complexities of compliance, ensuring a smooth transition and reducing the risk of regulatory hurdles.

Partner with Confidence

At Bora Biologics, we are dedicated to your success. Our proven track record in tech transfer, combined with our commitment to quality and client satisfaction, positions us as the ideal partner for your biopharmaceutical projects. Together, we can bring your innovations to market efficiently and effectively.

Connect With UsCell Line Development

tailored solutions for optimal biologics production

At Bora Biologics, our Cell Line Development services are designed to provide you with robust, high-yield cell lines tailored to meet the specific needs of your biopharmaceutical products. Our expertise in this critical phase of biologics development ensures that you have a solid foundation for successful manufacturing and commercialization.

Our Comprehensive Approach to CLD

We employ a systematic and scientifically rigorous approach to cell line development, encompassing the following key components:

-

Initial Design

and Selection - Gene Optimization

-

Clone Screening

and Selection -

Characterization

and Validation

Initial Design and Selection

Our process begins with a thorough assessment of your project requirements, including target product characteristics and production goals. We leverage advanced technologies to select the most suitable cell line platform, whether it be CHO, HEK293, or another proprietary system.

Gene Optimization

We utilize cutting-edge gene editing technologies, such as CRISPR/Cas9, to optimize the expression of your target protein. This optimization enhances yield, stability, and overall quality, ensuring that your cell line performs effectively throughout the production cycle.

Clone Screening and Selection

Our team conducts extensive screening of individual clones to identify those with the highest productivity and desired characteristics. This rigorous selection process guarantees that only the best-performing clones advance to the next stages of development.

Characterization and Validation

We perform comprehensive characterization of the selected cell lines, including stability assessments, growth kinetics, and protein expression profiling. This validation ensures that your cell line is well-defined and capable of consistently producing high-quality biologics.

Experts in Cell Line Development

Therapeutic Protein Production

Host cell bank qualification

CHO-K-derived cell line with clear history

Cell line development & monitoring

Accurate predictions using early data

Compliance with ICH

Monoclonality and documented traceability

Freedom-to-Operate

Host cell line and vectors developed In-House

Performance

4-6 g/L titer (pre-process development & optimization) with proven track record

Committed to Your Success in CLD

Working with Bora Biologics to develop our recombinant protein has been an excellent experience. Bora’s team has been fully engaged during the cell line and scale-up process and responsive to Technical and Quality requests. We hope to continue working with them to manufacture.

CEO of Q-Sera

Get Started Today

If you’re ready to develop a robust cell line for your biopharmaceutical project, contact us today. At Bora Biologics, we are committed to providing you with tailored solutions that enhance your product development journey from the very beginning.

Connect With UsMammalian Process Development

streamlined processes for reliable and cost-effective manufacturing

At Bora Biologics, our Mammalian Process Development services are designed to support the entire lifecycle of biopharmaceutical production, from early development through to commercial manufacturing. We specialize in optimizing both upstream and downstream processes to ensure high-quality, scalable production of biologics.

Our Expertise in Mammalian Process Development

Cell Culture Development

We focus on developing high titer, scalable production processes for a variety of molecules, including monoclonal antibodies (mAbs), to meet the demands of modern therapeutic applications.

Mammalian Cell Culture Optimization

Our expertise ensures optimal cultivation conditions, maximizing yield and quality throughout the production process.

Downstream Processing

Our downstream process development is customized to each unique protein, allowing us to create efficient purification schemes that maximize yield and quality. We employ high throughput resin screening and chromatography development to quickly identify the most effective purification methods. Additionally, our process includes comprehensive filtration development, encompassing depth filtration, sterile filtration, viral clearance, and tangential flow filtration (TFF). These innovative techniques streamline purification processes, ensuring that even the most complex molecules are handled effectively and safely.

Tailored Solutions

We understand that each mammalian process development project is unique. Our approach includes:

In our partnership with a leading biopharmaceutical company, Bora Biologics applied cutting-edge technology to their mammalian process development. Our efforts led to a 40% increase in yield while overcoming scale-up challenges. With our focus on compliance and efficiency, we enabled our client to concentrate on their innovative therapies, knowing they had a reliable partner in us.

Dr. Toby Hong, Director of Analytical & Upstream Process Development at

Bora Biologics

Proven Track Record

With years of experience in mammalian process development, our team has successfully advanced numerous projects from IND to BLA submission with seamless technology transfer and scale-up. Our commitment to excellence is reflected in our ability to deliver consistent, reliable, and cost-effective manufacturing solutions.

Why Choose Bora Biologics for Mammalian Process Development?

Expert Team

Our highly technical staff possesses extensive mammalian process development experience, enabling efficient parallel development activities and comprehensive process characterization.

Advanced Technologies

We leverage cutting-edge techniques and high-throughput technologies, including extensive use of DOE statistical software, to maximize product knowledge while minimizing experimentation requirements.

Quality Assurance

Our commitment to quality includes viral clearance study design and support, ensuring compliance with regulatory requirements. Our processes are aligned with manufacturing and quality control standards, facilitating seamless technology transfer.

Our Commitment to Innovation

At Bora Biologics, we are dedicated to continuous improvement and innovation in our mammalian process development services. We invest in the latest technologies and methodologies to enhance production efficiency, reduce costs, and improve product quality. By staying ahead of industry trends, we ensure that our clients benefit from the most effective and reliable solutions available.

Get Started Today

If you are looking to advance your biopharmaceutical project with a reliable partner in mammalian process development, contact us today to learn how Bora Biologics can support your goals. Our team is ready to collaborate with you to bring your innovative therapies to market efficiently and effectively.

Connect With UsMicrobial Process Development

streamlined processes for reliable and cost-effective manufacturing

At Bora Biologics, our Microbial Process Development services cater to the full lifecycle of biopharmaceutical production, from initial development through to commercial scale. We specialize in optimizing microbial fermentation processes to ensure high-quality, cost-effective production of biologics.

Our Expertise in Microbial Process Development

Fermentation Development

We focus on developing scalable fermentation processes for a variety of microbial systems, including E. coli and yeast, to produce proteins, enzymes, and other biologics.

Microbial Cell Culture Optimization

Our team specializes in optimizing microbial cell culture conditions to maximize yield and product quality. This involves fine-tuning parameters such as pH, temperature, and nutrient levels throughout the cultivation process.

Downstream Processing

We provide tailored downstream processing solutions for microbial-derived products. Our purification strategies are designed to efficiently isolate and purify target proteins while ensuring product integrity. We employ advanced techniques, including chromatography and filtration, to streamline purification and enhance yield.

Tailored Solutions for Microbial Process Development

Recognizing that every microbial process development project is unique, our approach includes:

Bora Biologics recently supported a client in microbial process development, where our expertise in fermentation and strain optimization made a significant impact. We achieved a 35% cost reduction in their production processes, streamlining their development efforts. Our commitment to empowering clients ensures they achieve their project goals faster, enhancing their competitiveness in the biopharmaceutical market.

Pawel Stanczak, PhD, Director, Process & Drug Product Development at Bora Biologics

Proven Track Record in Microbial Process Development

With years of experience in microbial process development, our team has successfully advanced numerous projects from IND to BLA submission with seamless technology transfer and scale-up. Our commitment to excellence is reflected in our ability to deliver consistent, reliable, and cost-effective manufacturing solutions.

Why Choose Bora Biologics for Microbial Process Development?

Expert Team

Our highly skilled staff possesses extensive experience in microbial process development, enabling efficient parallel development activities and comprehensive process characterization.

Advanced Technologies

We leverage cutting-edge fermentation technologies and high-throughput screening methods to maximize product yield while minimizing experimentation.

Quality Assurance

Our commitment to quality includes thorough process validation and compliance with regulatory requirements, ensuring that your products meet the highest standards.

Our Commitment to Innovation

At Bora Biologics, we are dedicated to continuous improvement and innovation in our microbial process development services. We invest in the latest technologies and methodologies to enhance production efficiency, reduce costs, and improve product quality. By staying ahead of industry trends, we ensure that our clients benefit from the most effective and reliable solutions available.

Start Your Microbial Process Development Project with Bora Biologics Today!

If you are looking to advance your biopharmaceutical project with a reliable partner in microbial process development, connect with us to learn how Bora Biologics can support your goals.

Connect With UsAnalytical Development

comprehensive solutions for biopharmaceuticals

At Bora Biologics, our Analytical Development services are designed to support the characterization and quality assessment of biologics throughout their lifecycle. We leverage state-of-the-art equipment and innovative techniques to ensure compliance and enhance product understanding, enabling the successful development of your biopharmaceuticals.

Our Analytical Capabilities

We provide a wide range of analytical services to assess both identity and purity, as well as to identify product-related and process-related impurities.

-

Product Related

Impurities -

Process Related

Impurities -

Structural

Characterization -

Biological / Functional

Characterization - Microbiology

-

Miscellaneous

Testing

Product Related Impurities

- Aggregation Size Variants

- Analyzed by SE-HPLC, SEC-MALS, and CE-SDS

- Charge Variants

- Evaluated using Ion Exchange Chromatography (IEX) and Capillary Isoelectric Focusing (cIEF)

- Hydrophobicity Variants

- Assessed for oxidation and Drug-Antibody Ratio (DAR) variants by RP-HPLC and HIC, along with released glycans via HILIC and post-translational modification (PTM) analysis by LC-MS

Process Related Impurities

- Host Cell Proteins (HCP)

- Host Cell DNA (hcDNA)

- Antifoam and Surfactants

- Protein A

Structural Characterization

- Primary Structure

- Intact mass analysis

- Peptide mapping

- Sequence variant analysis by LC-MS

- Higher Order Structure

- Disulfide bond analysis

- Free thiol quantification

- Far- and near-UV Circular Dichroism (CD)

Biological / Functional Characterization

- Cell-based potency assays (e.g., proliferation and inhibition)

- ADCC characterization using DELFIA (TRF) or reporter gene assays

- Signaling pathway characterization

- Ready-to-thaw cell banks

- ELISA and AlphaLISA® assays

- Surface Plasmon Resonance (SPR)

Microbiology

- Bioburden and endotoxin testing

Miscellaneous Testing

- Analysis of excipients, including polysorbate and PEG

- Amino acid analysis, particulates, and titer assessments

Our Analytical Equipment

Our facilities are outfitted with cutting-edge analytical equipment, ensuring high-quality results and compliance at every phase of your program:

- HPLC & UPLC Systems

- High-Resolution Mass Spectrometers

- CE-SDS and icIEF Systems

- MALS and Semi-Preparative HPLC Systems

- Plate Readers and Vi-CELL Automatic Cell Counters

- UV/Vis Spectrophotometers

- HIAC Particle Counters and Sievers Total Organic Carbon Analyzers

- ICH Compliant Stability Storage and Cryo Freezers

- Photostability Chamber and Tecan Liquid Handler

Why Choose Bora Biologics for Analytical Development?

Expert Team

Our analytical scientists possess extensive experience in biologics characterization, ensuring that your products meet regulatory standards and industry best practices.

Advanced Technologies

We utilize cutting-edge analytical techniques and equipment to provide reliable and accurate data, enhancing your product development process.

Commitment to Quality

Our rigorous quality assurance programs ensure that your biopharmaceuticals remain compliant and of the highest quality at every stage of development.

Hear from Our Experts

Strategies and Tactics for Success in Biologics Analytical Testing

Customized Solutions for Biologics Development: Leveraging Adaptive Platforms to Meet Customer Needs

Designing Quality into Biomanufacturing: A Proactive Approach to Efficiency and Compliance

Developing a Toolbox of Functional Bioassays for Optimizing ADCC

Analysis of Therapeutic Monoclonal Antibodies Using a Platform Size Exclusion-HPLC Method

More Discoveries

Start Your Analytical Development with Bora Biologics

If you are looking for reliable analytical development services to support your biopharmaceutical projects, connect with us to learn how Bora Biologics can help you achieve your goals efficiently and effectively.

Connect With UsFormulation & Drug Product Development

innovative solutions for advancing biopharmaceuticals

At Bora Biologics, we specialize in Formulation and Drug Product Development, focusing on creating safe, effective, and stable biopharmaceutical products tailored to meet the unique needs of our clients. Our comprehensive capabilities ensure that your drug products are developed with precision and care, leveraging cutting-edge technologies and methodologies.

Drug Product Development Capabilities

With a commitment to innovation and optimization, our drug product development services include:

- High Throughput Pre-Formulation Screening

- Drug Product and Formulation Development

- Biophysical Characterization

- Spectroscopy-Based Assay Development

- Thermal and Kinetic Stability Assessment

- Excipient Compatibility Studies

- Pooling and Mixing Characterization

- Filtration and Integrity Assessments

- Filling Process Characterization

- Extractable and Leachable Assessment

- Drug Product Package Selection and Testing

- Drug Product Shipping Assessment

- Regulatory Drafting and Audit Support

- DP Administration and IV Bag Compatibility

High Throughput Pre-Formulation Screening

Rapid assessment of formulation conditions to identify optimal parameters for drug stability and efficacy.

Drug Product and Formulation Development

Tailored solutions that encompass all aspects of formulation to enhance product performance.

Biophysical Characterization

Comprehensive analysis of physical properties to ensure product stability and efficacy.

Spectroscopy-Based Assay Development

Utilizing advanced spectroscopy techniques to develop reliable assays for quality control.

Thermal and Kinetic Stability Assessment

Evaluating the stability of drug products under various conditions to ensure long-term efficacy.

Excipient Compatibility Studies

Assessing the compatibility of excipients with active pharmaceutical ingredients (APIs) to ensure formulation integrity.

Pooling and Mixing Characterization

Analyzing the effects of pooling and mixing on formulation stability.

Filtration and Integrity Assessments

Comprehensive evaluations of filtration processes, including compatibility, integrity, and bacterial retention support.

Filling Process Characterization

Detailed assessments of the filling process to ensure product quality and compliance.

Extractable and Leachable Assessment

Evaluating manufacturing components for potential extractables and leachables to guarantee product safety.

Drug Product Package Selection and Testing

Rigorous assessment of packaging options, including functional studies for syringes and compatibility testing

Drug Product Shipping Assessment

Ensuring that drug products maintain integrity throughout the shipping process.

Regulatory Drafting and Audit Support

Providing expert guidance and documentation to facilitate regulatory compliance.

DP Administration and IV Bag Compatibility

Assessing compatibility of drug products with intravenous administration systems.

Integrated Allosteric Formulation Development Platform

Our cutting-edge Allosteric Formulation Development Platform enables fast, economical, and precise formulation development for a variety of biologics, including:

- Monoclonal antibodies and their fragments

- Antibody-Drug Conjugates (ADCs)

- Cytokines, enzymes, and growth factors

- Synthetic peptides and recombinant fusion proteins

- Liposomes, lipid nanoparticles (LNPs), micelles, and polymers

Biophysical and Analytical Platforms

We employ advanced biophysical and analytical techniques to ensure comprehensive characterization of drug products:

- Biophysical High Throughput Platform

- Spectroscopy Techniques: Fluorescence, CD, NMR, ESR, FTIR, Raman, and Light Scattering (LS)

- Biophysical Techniques: Differential Scanning Calorimetry (DSC), Analytical Ultracentrifugation (AUC), and Surface Plasmon Resonance (SPR)

- Analytical Platform

- A variety of HPLC-based methods (e.g., SEC, RP, CEX, HIC, HILIC), MALS, cIEF, CE-SDS, and mass spectrometry (MS)

- Comprehensive assessments of osmolality, particle size (HIAC), morphological characterization (MFI), photostability, pH, viscosity, and protein concentration/solubility (A280/350)

- Design of Experiments (DOE) and statistical analysis using JMP and GraphPad

Why Choose Bora Biologics for Formulation & Drug Product Development?

Expertise in Biologics

Our experienced team is well-versed in the complexities of biologics formulation, ensuring that your products meet both efficacy and safety standards.

Innovative Platforms

Our unique formulation platforms enable rapid development and adaptation to various biologic formats, ensuring flexibility in your drug development process.

Commitment to Quality

We prioritize quality assurance at every stage of development, ensuring compliance with regulatory standards and the highest product integrity.

Hear from Our Experts

Designing Quality into Biomanufacturing: A Proactive Approach to Efficiency and Compliance

Redefining Scalability: Strategies for Enhancing Early Drug Development to Future-Proof Later Stages

Customized Solutions for Biologics Development: Leveraging Adaptive Platforms to Meet Customer Needs

Analysis of Therapeutic Monoclonal Antibodies Using a Platform Size Exclusion-HPLC Method

More Discoveries

Start Your Formulation & Drug Product Development with Bora Biologics

If you are looking for innovative and reliable formulation and drug product development services, connect with us to learn how Bora Biologics can help you bring your biopharmaceuticals to market efficiently and effectively.

Connect With Us

Bora Biologics

the logical choice

Join the ranks of biopharma pioneers who trust us.

Explore how we minimize risks and accelerate your success.

Client-Centric

100% commitment to supporting your success

Experience

14 years developing & manufacturing biologics

Expertise

125 seasoned scientists & regulatory professionals

Commercial-Ready

US FDA registered GMP manufacturing facility

Allied

access to global CDMO resources