Manufacturing Excellence

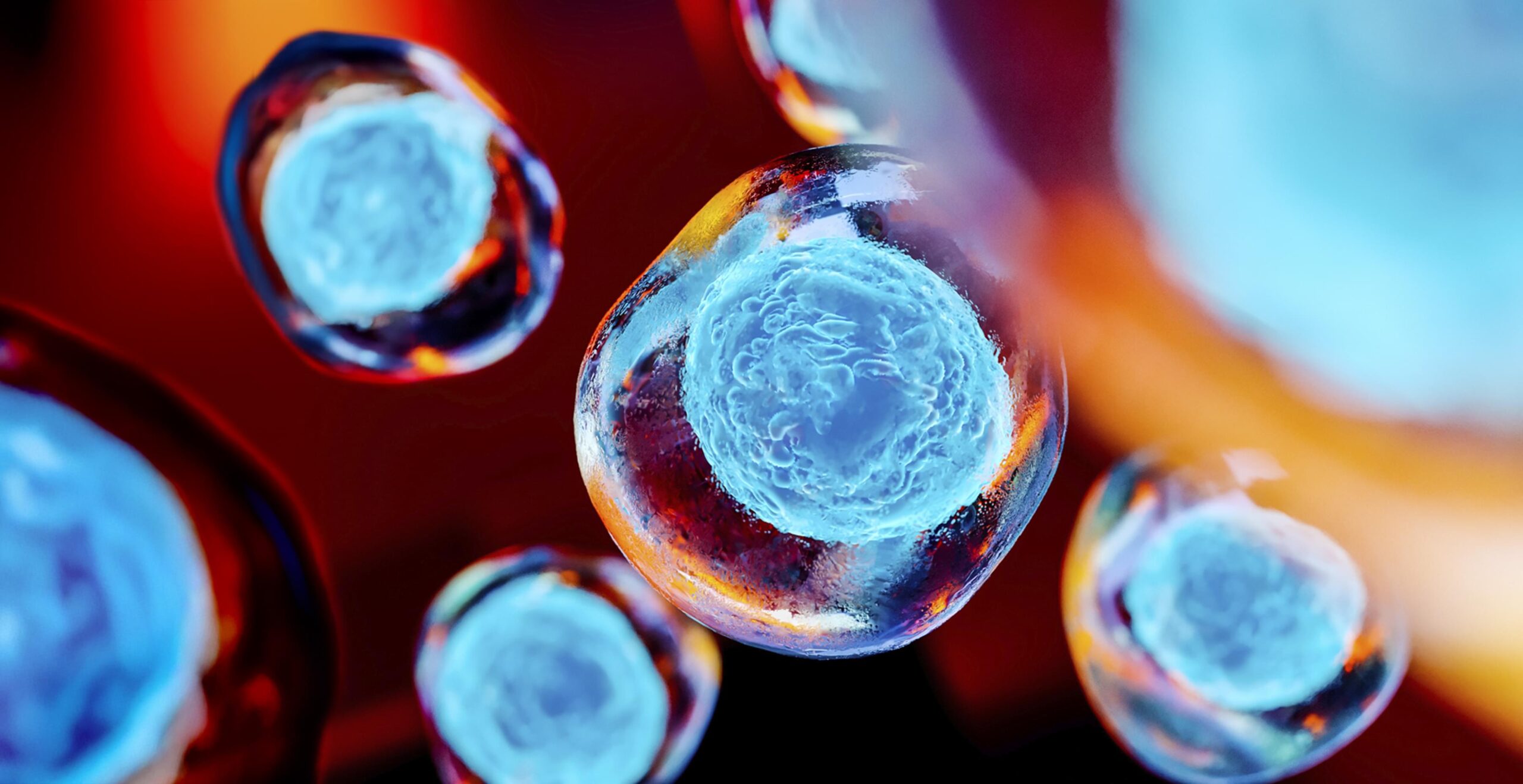

transforming biologics manufacturing

Bora Biologics combines decades of expertise, state-of-the-art facilities, and a commitment to innovation, to position ourselves as an industry leader in biologics manufacturing.

Our Manufacturing Capabilities

We offer a comprehensive suite of services to meet the evolving needs of our clients:

-

Full-Service Biologics

Manufacturing -

Next-Gen

Technology -

Expertise in

Various Modalities -

Analytical Method

Development

Full-Service Biologics Manufacturing

From early-stage development to commercial production, we provide end-to-end solutions tailored to your specific requirements. We specialize in process development to GMP manufacturing scaling up to 2000L batches.

Next-Gen Technology

Our cutting-edge facilities are equipped with the latest equipment and upgraded technologies, ensuring efficient and scalable manufacturing processes. We utilize state-of-the-art single-use systems and fully integrated platforms that enhance flexibility and significantly reduce turnaround times. This commitment to innovation allows us to adapt quickly to changing project requirements and maintain the highest quality standards.

Expertise in Various Modalities

We specialize in a wide range of biologics, including fusion proteins, antibodies and antibody derivatives, bi- and tri-specifics, ADC’s, enzymes, and more. Our experienced team is dedicated to delivering high-quality products that meet stringent regulatory standards.

Analytical Method Development

Leveraging our biosimilar experience, we provide rapid, effective, and tailored analytical solutions to ensure product comparability and compliance with regulatory requirements. We offer exceptional analytical methods to accurately characterize and evaluate comparability.

Quality Assurance at Every Step

Quality is at the core of everything we do. Our robust Quality Management System (QMS) is designed to ensure compliance with global regulatory requirements, including GMP standards. With a focus on continuous improvement, we implement rigorous testing and validation processes throughout the manufacturing lifecycle.

Quality Control & Assurance

Our mature QMS employs rigorous testing protocols, ensuring the safety, identity, strength, and purity of every product.

Explore Our Quality Control & Assurance ProcessesSupply Chain Management

A robust supply chain is the backbone of a successful biopharmaceutical program, from GMP warehousing to inventory and vendor management.

Explore Our Supply Chain AdvantagesProgram Management

Our timeline-driven collaborative approach ensures your vision is realized, expectations are met, and projects progress seamlessly.

Explore Our Program Management Philosophy

Impressive Achievements

At Bora Biologics, we prioritize your success by leveraging our expertise and resources to deliver exceptional results in biologics manufacturing.

State-of-the-Art Facilities

Our combined manufacturing footprint spans over 130,000sf featuring modular cleanrooms and advanced single-use bioreactor trains to support large-scale production. Explore Facilities

Proven Track Record

With over 45 biologics and biosimilars developed, over 100 successful cGMP batches delivered, 2 commercially approved biosimilars in U.S. and Canada, and partnerships with leading pharmaceutical and biotech companies, we have established ourselves as a trusted partner in the biologics industry.

Expert Team

Our diverse team of scientists, engineers, and regulatory experts possesses a wealth of knowledge and experience, ensuring you benefit from the best practices in biologics manufacturing.

Partner with Confidence

At Bora Biologics, we are dedicated to your success. Our proven track record in tech transfer, combined with our commitment to quality and client satisfaction, positions us as the ideal partner for your biopharmaceutical projects. Together, we can bring your innovations to market efficiently and effectively.

Connect With UsMammalian GMP Manufacturing

precision and excellence in mammalian cell culture

At Bora Biologics, our Mammalian GMP Manufacturing capabilities are designed to meet the highest industry standards, ensuring the production of safe and effective biologics. Equipped with advanced single-use technologies for efficient production, and a commitment to quality, we deliver scalable solutions tailored to your specific needs.

Our mammalian facilities meet stringent GMP guidelines, minimize cross-contamination risks, and facilitate rapid change.

State-of-the-Art Facilities

Our FDA-registered and GMP-compliant facilities feature dedicated mammalian manufacturing suites, single-use technology, purification suites, media and buffer prep and autoclave/wash – with capacity and flexibility to scale production efficiently. Single-use bioreactor capacity includes:

- 2 x 50L

- 2 x 250L

- 4 x 500L (+2 Q1 2026)

- 4 x 1000L

- 2 x 2000L (Q1 2026)

Robust Cell Line Development

Utilizing our own CHO cell line with cutting-edge techniques for cell line development, we ensure optimal expression and yield of your biologics. Our expertise encompasses a range of mammalian systems, including CHO and HEK293 cells.

Explore CLD Capabilities

Process Development and Optimization

Our experienced team works closely with you to develop and optimize manufacturing processes that enhance product quality, reduce costs, and shorten timelines. We employ advanced technology to ensure the highest quality standards:

- in-house Water for Injection (WFI)

- AKTA chromatography systems

- automated Tangential Flow Filtration (TFF) skids

- viral filtration skids

- ambr250 bioreactor systems for high-throughput process development

The integration of ambr250 allows us to rapidly evaluate and optimize cell culture conditions, facilitating faster scale-up and improved process efficiency.

Explore Mammalian Process Development Capabilities

Explore Microbial Process Development Capabilities

Your Success is Our Priority

Bora Biologics’ team, with their extensive experience, profound professional knowledge, and strong international communication skills, has been crucial to the rapid progress of our Nano-TriTE project.

Deputy General Manager, Shine-On BioMedical

Let’s Get Started

If you’re looking for a reliable partner for your mammalian GMP manufacturing needs, contact us today. We are dedicated to supporting your journey from concept to commercialization.

Connect With UsMicrobial GMP Manufacturing

efficient and reliable solutions for microbial-derived biologics

Advanced Microbial Facilities and Technologies

At Bora Biologics, we have been meeting the demand for speed and cost-effectiveness in microbial-derived biologics since 2011. Our commitment to excellence is reflected in our optimized strain selection, fermentation, and purification processes, ensuring that your products are developed and manufactured efficiently.

-

High-Yield

Fermentation -

Comprehensive

Downstream

Purification Options - Scalable Production

- AKTA Ready

- Automated TFF Skids

High-Yield Fermentation

Our microbial GMP manufacturing suites are equipped with cutting-edge fermentors that facilitate high-yield fermentation processes, allowing for the production of both secreted and intracellular products.

- 1 x 150L SS Fermentor

- 1 x 300L SUF (+ Q1 2026 planned expansion)

Comprehensive Downstream Purification Options

We offer a variety of downstream purification strategies tailored to meet the specific requirements of your biologics, ensuring high purity and activity levels.

Scalable Production

From pre-clinical to commercial scale, our flexible manufacturing capabilities adapt to your project’s needs, enabling seamless transitions throughout the development stages.

AKTA Ready

Our facilities are equipped with AKTA chromatography systems, ensuring efficient and precise purification of your biologics.

Automated TFF Skids

Utilizing automated Tangential Flow Filtration (TFF) skids, we enhance the efficiency and consistency of our purification processes, minimizing manual intervention and reducing risk.

Committed to Your Success

Bora Biologics

the logical choice

Join the ranks of biopharma pioneers who trust us.

Explore how we minimize risks and accelerate your success.

Client-Centric

100% commitment to supporting your success

Experience

14 years developing & manufacturing biologics

Expertise

125 seasoned scientists & regulatory professionals

Commercial-Ready

US FDA registered GMP manufacturing facility

Allied

access to global CDMO resources